Coil Corrosion

An article from Bronz-Glow. Visit Bronz-Glow’s website at www.bronz-glow.com

There are many forms of corrosion. However, the most common form of corrosion associated with HVAC equipment is referred to as galvanic or general corrosion. This type of corrosion can lead to equipment failure.

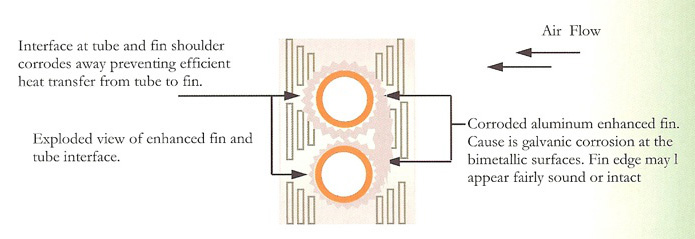

Galvanic corrosion causes fin degradation, which leads to the destruction of the coil. Galvanic corrosion of a coil appears at the interface of the fin and tube. This is a bi-metallic interface between the copper tube and aluminum fin.

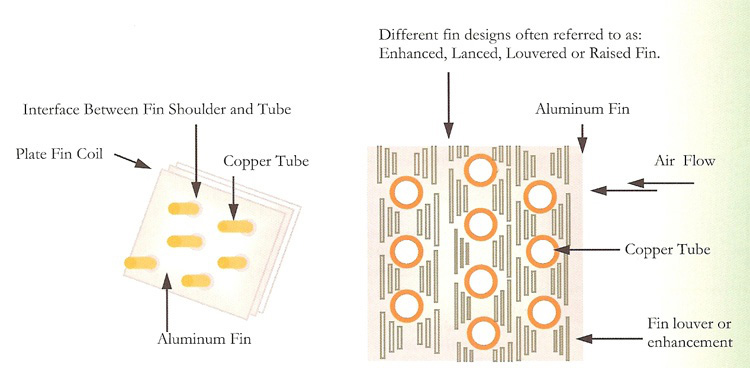

Figure 1: Basic Construction Non-louvered and Louvered Fins

Figure 2: Galvanic Corrosion begins at the bi-metallic interface of the aluminum fin and copper tube.

As corrosion begins at the interface of the tube and fin, the fin deteriorates and lost metal creates gaps or voids between the tube and fin shoulder or surface degrading the coil efficiency which reduces optimum coil performance. Visual destruction of the coil from corrosion is evident. Repair through coating is not suggested, since there is no way to bridge the gap between the fin and tube interface once corrosion had deteriorated this joint or the fins become too brittle.